Overview

Apple is accelerating its strategy to shift iPhone production from China to India as part of its response to the escalating U.S.-China trade tensions and the need for supply chain diversification. The company is set to begin production of its latest models, the iPhone 16 and 16e, in India, with a goal of producing the majority of iPhones sold in the U.S. from India by 2026. This initiative is being spearheaded by key partners Tata Electronics and Foxconn, who are ramping up their operations and expanding production capacity in India. As India emerges as a crucial production hub and a growing consumer market, this shift is expected to have significant implications for the global technology supply chain.

Detailed Report

Apple’s Expansion Strategy in India: Accelerating 'Decoupling from China'

For many years, Apple maintained a production base primarily in China. However, recent geopolitical risks and supply chain uncertainties have prompted the company to actively pursue diversification of its production facilities. The intensification of U.S.-China trade tensions, particularly under the Trump administration, has made the need for a 'decoupling' strategy more pressing for Apple.

India has been chosen as a key location for this strategy due to its attractive factors, including a large labor force, significant domestic market potential, and supportive government policies aimed at boosting manufacturing (such as the Production-Linked Incentive scheme) . Apple aims to leverage India as a major production base to stabilize its supply chain, avoid tariff burdens, and enhance its influence in the Indian market.

Target for U.S. iPhone Production: Apple has set a goal to produce the majority of iPhones sold in the U.S., approximately 60 million to 65 million units annually, from India by the end of 2026. This target significantly exceeds the current production capacity in India, which is estimated at around 40 million units. To achieve this, Apple is strengthening its partnerships with Tata and Foxconn and significantly increasing its investments in production facilities in India.

New Factory Operations and Production Status

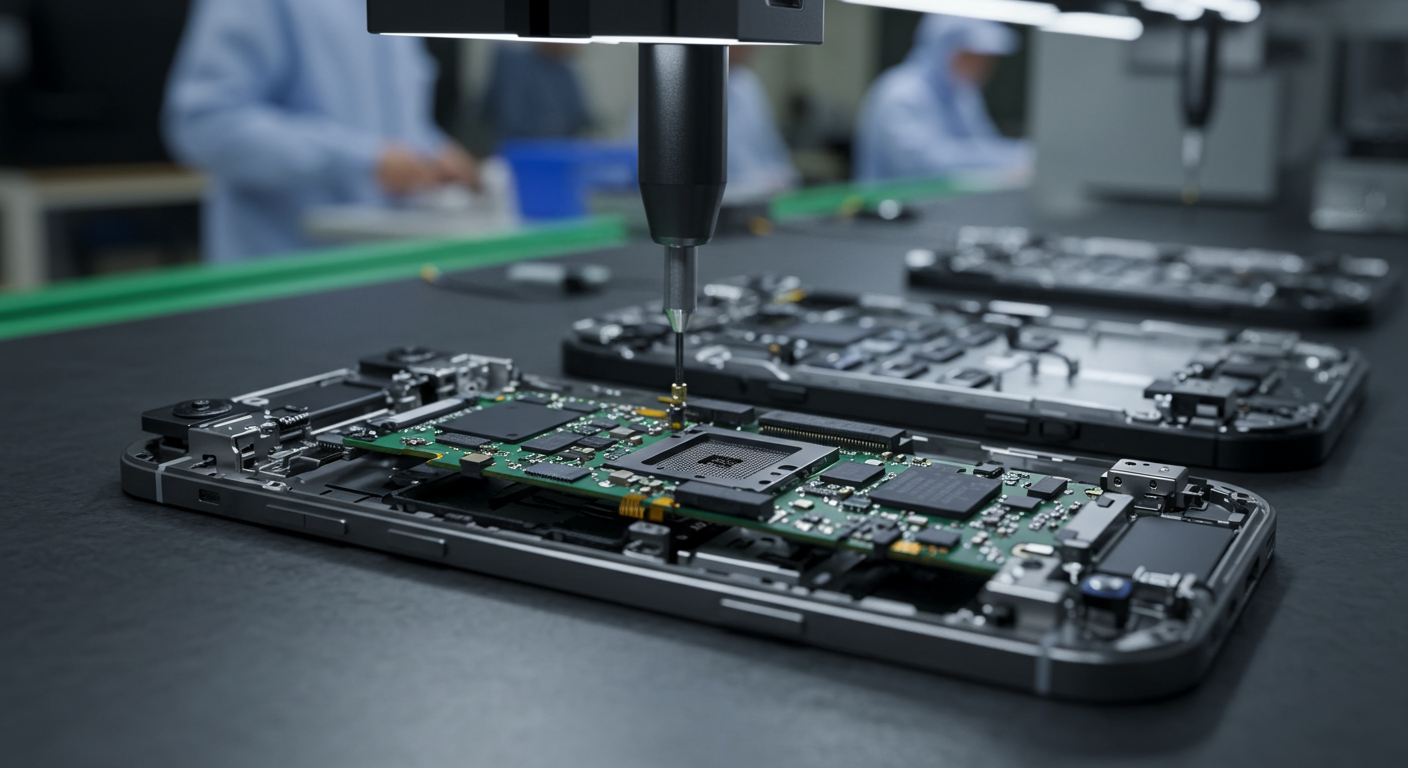

Apple's strategy for expanding production in India is being realized through its key partners, Tata Electronics and Foxconn. Both companies are constructing new factories and expanding existing facilities to increase iPhone production capacity.

Tata Electronics:

- Hosur Factory Operations: Tata Electronics has recently commenced operations at its new factory located in Hosur, Tamil Nadu. Currently, this factory is assembling older iPhone models on a single assembly line.

- Large-Scale Expansion Plans: Tata aims to develop the Hosur factory into one of the largest iPhone assembly plants in India. Within the next two years, it plans to establish around 20 assembly lines and create 50,000 jobs. Tata has been involved in producing iPhone cases and components for some time, and in 2023, it acquired Wistron’s Karnataka factory to enter the iPhone assembly business.

- Fire Incident and Resumption of Operations: In September 2024, a fire broke out at the Hosur factory, temporarily halting production; however, operations resumed in early October.

Foxconn:

- Bengaluru New Factory: Foxconn, Apple’s largest partner, is constructing a massive new factory in Bengaluru, Karnataka, with an investment of $2.6 billion (approximately 3.5 trillion KRW). This factory, referred to as 'Project Elephant,' is expected to become the second-largest Foxconn facility outside of China upon completion, covering an area equivalent to 220 soccer fields.

- Production of iPhone 16/16e: The new factory is set to begin initial operations soon and will produce the latest models, including the iPhone 16 and the budget-friendly iPhone 16e. Initially, it will start with one assembly line capable of producing 300 to 500 iPhones per hour, with plans to create up to 50,000 jobs by 2027.

Doubling Production Goals: Foxconn plans to double its iPhone production in India to 25 million to 30 million units annually by 2025, as requested by Apple. It is already reported to be conducting trial production at the new factory.

Current Production

Share and Goals

Thanks to aggressive investments and production expansions, the share of iPhones produced in India is rapidly increasing.

- Current Share: India currently accounts for approximately 18-20% of global iPhone production. This is a significant increase from just 5-7% a few years ago. For the fiscal year 2024 (April 2023 - March 2024), the value of iPhones produced in India is estimated to be around $22 billion (approximately 31 trillion KRW), reflecting a more than 60% increase year-on-year.

- Short-Term Goals (2-3 Years): Apple and its suppliers aim to produce over 50 million to 60 million iPhones in India within the next 2-3 years. If achieved, this would mean India would account for 25% of global iPhone production.

- Long-Term Goals (Post-2027): Some forecasts suggest that by 2027, the share of iPhone production in India could reach as high as 50%.

The table below illustrates the changes in Apple’s iPhone production bases.

CategoryEstimated 2022Estimated 2023Target for 2025 (Some Predictions)Target for 2027 (Some Predictions)| China | ~80% | ~70% | - | ~50% |

| India | ~12% | ~20% | ~25% | ~50% |

| Others | ~8% | ~10% | - | - |

(Note: The figures in the table are estimates and predictions from various sources and may differ from actual values.)

Accelerating the Shift of U.S.-Bound iPhone Production

One of the most notable aspects of Apple’s expansion strategy in India is the shift of U.S.-bound iPhone production. This move is seen as a key measure to mitigate tariff burdens amid ongoing U.S.-China trade tensions.

- Motivation for Avoiding Tariffs: The U.S. currently imposes high tariffs on products from China, which increases the pressure to raise iPhone prices. In contrast, products made in India may benefit from lower or no tariffs, allowing Apple to maintain price competitiveness and profitability.

- Large-Scale Volume Shift Plans: Apple aims to produce the majority of iPhones sold in the U.S. from India, approximately 60 million to 65 million units annually, by the end of 2026. This target significantly exceeds the current production capacity in India (estimated at around 40 million units) .

- Emergency Shipping Cases: Following the announcement of tariffs, Apple urgently shipped approximately 600 tons (estimated at around 150,000 units) of iPhones produced in India to the U.S. in March. This case exemplifies Apple’s commitment to shifting U.S.-bound production to India.

- Potential to Meet U.S. Demand: Some analysts estimate that the current annual production capacity in India (approximately 25 million to 40 million units) could meet about 50% of U.S. market demand. If Apple achieves its production targets, it could feasibly supply most of the U.S. market with iPhones made in India.

Support from the Indian Government and Challenges

Apple’s expansion in India is significantly supported by proactive government policies. However, there are also challenges that need to be addressed.

- Production-Linked Incentive (PLI) Policy: The Indian government has implemented the PLI scheme since 2020 to promote manufacturing. This scheme provides subsidies to companies based on the increase in production and investment in India, benefiting Apple’s key suppliers like Foxconn and Pegatron. This has been a crucial incentive for Apple’s investment decisions in India.

- Challenges and Obstacles:

- Infrastructure and Regulations: India still faces challenges with its logistics infrastructure and complex labor regulations, making operations more difficult compared to China.

- Cost Issues: While hourly wages are lower than in China, other costs such as import tariffs (recently reduced), logistics, and operational expenses may be higher, potentially leading to production costs that are 7-8% higher than in China.

- High Selling Prices: iPhones in India tend to be priced higher than in other countries due to high Goods and Services Tax (GST, 18%) and dealer margins (10-12%). Consequently, the price reduction effect from local production may be limited.

- Chinese Resistance: There are concerns that the Chinese government may resist the relocation of iPhone production to India, potentially delaying the export of production equipment to India.

Production of iPhone 16 and 16e Models

The production of Apple’s latest flagship models, the iPhone 16 series, is becoming increasingly significant in India.

- Production of Base and e Models: The new factory being constructed by Foxconn in Bengaluru is set to produce the iPhone 16 and the budget-friendly iPhone 16e. In the past, India primarily produced older or lower-cost models, but starting with the iPhone 14, production of newer base models began, and the scope is expected to expand further with the iPhone 16 series.

- Potential Production of Pro Models: There are reports that some quantities of the iPhone 16 Pro and Pro Max models will also be produced in India for the first time. This indicates that India is evolving from a simple assembly hub to a producer of high-value products. The iPhone 16 Pro models produced in India are expected to be exported to the U.S., Europe, and other regions.

이미지를 불러올 수 없습니다 - Global Simultaneous Launch?: Previously, iPhones produced in India were launched with a delay compared to global releases, but starting with the iPhone 15, Indian-made models began to be supplied at the initial launch, and there is a possibility that Indian-made iPhone 16 series will be supplied to the global market more quickly.

Conclusion

Apple’s expansion of iPhone production in India is the result of a complex interplay of factors, including U.S.-China trade tensions, the need for supply chain diversification, and the growth potential of the Indian market. The ramp-up of production by Tata Electronics and Foxconn, along with the goal of shifting the majority of U.S.-bound iPhone production to India by 2026, underscores Apple’s commitment to this strategy.

This shift not only provides Apple with advantages in terms of mitigating tariff burdens and enhancing supply chain stability but also promises positive effects on India’s economic growth through increased manufacturing, job creation, and technology transfer. India is set to become a crucial production hub and strategic market for Apple.

However, challenges such as infrastructure, regulations, costs, and quality control remain. It will be essential to monitor how Apple overcomes these challenges and achieves its production goals in India, as well as the long-term impacts of these changes on the global technology industry and supply chain dynamics. Apple’s expansion in India represents a significant shift that goes beyond mere relocation of production facilities, reflecting broader trends in the global economy and competition for technological supremacy.

'경제뉴스' 카테고리의 다른 글

| Victory Day 80th Anniversary Summit: Xi and Putin Chart a Multipolar World (0) | 2025.05.05 |

|---|---|

| आईपीएल, सिर्फ एक खेल से बढ़कर एक घटना: जन्म से लेकर भविष्य तक का गहन विश्लेषण (0) | 2025.05.03 |

| SKT 해킹 여파, 알바몬에서도 개인정보 유출 발생 (0) | 2025.05.02 |

| 대선 앞두고 주 4.5일제 논쟁 격화 갈등 대립 (2) | 2025.05.02 |

| SKT사태 개인정보유출사례 및 방지방법 공유 (2) | 2025.04.30 |